Introduction

The oil and gas industry is known for its demanding and challenging operating conditions, requiring reliable power sources to ensure continuous operations. In this regard, diesel generators play a crucial role in providing backup power solutions for oil and gas facilities. This article explores the importance of diesel generators in the oil and gas industry, their key features, applications, and the factors to consider when selecting a diesel generator for oil and gas operations.

Overview of Diesel Generators

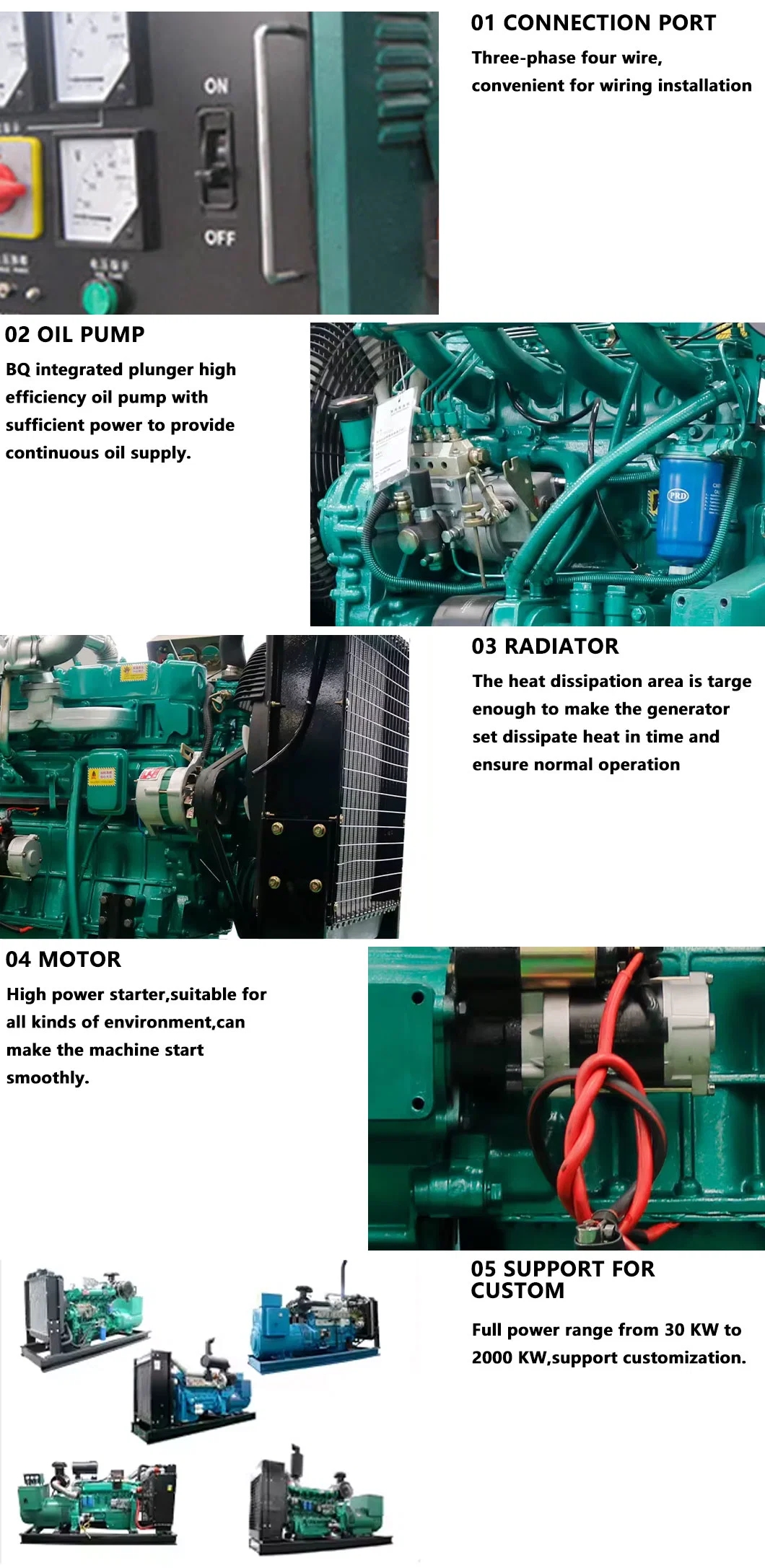

Diesel generators are a type of backup power source that utilizes a diesel engine to generate electricity. They are widely used in various industries, including the oil and gas sector, due to their reliability, durability, and fuel efficiency. Diesel generators are capable of producing large amounts of power and can operate for extended periods, making them ideal for providing backup power in critical applications.

Key Features of Diesel Generators for the Oil and Gas Industry

Diesel generators offer several key features that make them well-suited for use in the oil and gas industry. Some of the key features include:

1. Reliability: Diesel generators are known for their reliability and robustness, making them suitable for providing backup power in critical applications where uninterrupted power supply is essential.

2. Durability: Diesel generators are designed to withstand harsh operating conditions, making them ideal for use in oil and gas facilities located in remote or challenging environments.

3. Fuel Efficiency: Diesel generators are more fuel-efficient compared to other types of generators, making them a cost-effective power solution for oil and gas operations.

4. Power Output: Diesel generators are capable of producing high power output, making them suitable for powering heavy machinery and equipment used in the oil and gas industry.

5. my review here : Diesel generators are relatively easy to maintain, with routine servicing and maintenance ensuring optimal performance and longevity.

Applications of Diesel Generators in the Oil and Gas Industry

Diesel generators find widespread applications in the oil and gas industry, where reliable backup power is critical for maintaining operations. Some of the common applications of diesel generators in the oil and gas sector include:

1. Offshore Platforms: Offshore oil and gas platforms require reliable power sources to operate essential equipment and machinery. Diesel generators are often used as backup power sources on offshore platforms to ensure continuous operations in case of power outages.

2. Onshore Facilities: Onshore oil and gas facilities, such as refineries, processing plants, and pumping stations, rely on diesel generators to provide backup power during grid failures or emergencies.

3. Exploration and Drilling: Diesel generators are used in exploration and drilling operations to power drilling rigs, pumps, and other equipment in remote locations where grid power is not available.

4. Emergency Response: Diesel generators are essential for emergency response teams in the oil and gas industry to provide power for communication systems, lighting, and other critical equipment during emergencies or natural disasters.

Factors to Consider When Selecting a Diesel Generator for Oil and Gas Operations

When selecting a diesel generator for oil and gas operations, several factors need to be considered to ensure the generator meets the specific requirements of the application. Some of the key factors to consider include:

1. Power Output: The power output of the diesel generator should be sufficient to meet the electrical load requirements of the oil and gas facility, including peak demand and starting currents of equipment.

2. Fuel Efficiency: Consider the fuel efficiency of the diesel generator to minimize operating costs and fuel consumption over the generator's lifespan.

3. Environmental Regulations: Ensure that the diesel generator complies with environmental regulations and emissions standards to minimize its impact on the environment.

4. Maintenance Requirements: Evaluate the maintenance requirements of the diesel generator, including service intervals, spare parts availability, and service provider support.

5. Noise Level: Consider the noise level of the diesel generator, especially for applications in sensitive environments where noise pollution is a concern.

6. Integration with Existing Systems: Ensure that the diesel generator can be seamlessly integrated with the existing power distribution system and control systems at the oil and gas facility.

7. Remote Monitoring and Control: Look for diesel generators with remote monitoring and control capabilities to enable real-time monitoring of performance, fuel levels, and alerts for maintenance requirements.

Conclusion

Diesel generators play a vital role in the oil and gas industry by providing reliable backup power solutions for critical applications. Their key features, including reliability, durability, fuel efficiency, and high power output, make them well-suited for use in oil and gas facilities operating in challenging environments. When selecting a diesel generator for oil and gas operations, it is essential to consider factors such as power output, fuel efficiency, environmental regulations, maintenance requirements, noise level, integration with existing systems, and remote monitoring capabilities to ensure optimal performance and reliability. By choosing the right diesel generator for their specific needs, oil and gas companies can ensure uninterrupted operations and minimize downtime in case of power outages or emergencies.